Propane Smelting Furnaces Metal Melting Furnace Kits

Table of Content

A basic metal casting facility setup in either the backyard or the home for hobby metal professionals to create small metal castings for different needs is referred to as Home Foundry. Such a DIY Aluminum Foundry is different from a commercial foundry as it is usually set up with materials and equipment available easily in the market and is used to carry out simple metal casting jobs. Using simple processes for designing, pattern making and mold making, metal casting hobbyists can create different things easily in home foundry. If you’re interested in smelting and metal working, Cast Master Elite has the solutions for you. Our propane smelting furnaces are specially made for any metal project, whether you’re into jewelry making, refining, metalsmithing, or casting.

Factored in are contemporary concerns, including access to the internet and cell phone service and the importance of an effective security system. Chapter summaries drive home key points for success, and a list of resources directs readers to key information. Do you aspire to live a green or zero-waste life, but just don’t know where to begin?

Aluminum Casting At Home – DIY Aluminum Foundry & Molds

Depending on the size of castings you are required to make, you can make the flask large or small. If required, the depth of the flask can be increased by fitting a simple 4 sided cheek between the components. Imagine, you have just found that you can melt and cast metals in your own backyard foundry and you feel excited at the possibility of making your very own metal castings. The excitement grows as you begin to slowly understand the; how, what & when of this traditional metal craft. You’ll be inspired to dive deeper into green living and feel empowered by your choice to help the environment and create a healthier household. Many people across the globe produce their own superior quality bronze and aluminum castings for vintage and veteran motorcycles and cars.

Due to the extreme temperatures created inside the furnace, it is important to line the floor, inner walls and lid with a refractory material. You can mix up the required quantity and follow the instruction on the bag and fill the material at the bottom of your furnace container. You can then fill the wall cavity with the refractory and finally line the lid.

Build Your Own Home Metal Foundry

The hole should be sufficiently to fit a 16" section of 1-1/2" feed pipe. After this, weld the assembly to the wall of canister, with the elbow pointing in upward direction. Next, make a hole in the middle of lid section, and weld a small length of 2 & quot the muffler tubing in place, permitting it to protrude below the lid's lip lightly. Then fix some handles—made from small pieces of 1/8" X 3/4" flat stock and 6" pieces of 1/2" pipe—to the sides of the faces of container. John Vivian's guide to mastering the ancient art of metalworking takes you from basic tools to working with metals as various as bronze and high-carbon steel.

When the metal has cooled and solidified, it is taken out from the sand, which is now a shiny new metal casting. Ever thought you could yourself melt sufficient brass or aluminum to create small castings for a special need or project. Well, this is true for many people, who dream about casting metals in their home.

Featured work at KIT Royal Institute

They are hobby metal professionals who like to cast metals to fulfill their creative desires or to make a special part or component, which is difficult to find in the market. The sand mold creating process involves use of a metal, furnace, sand mold and pattern. The aluminum is melted in the furnace and then poured into the cavity of the sand mold formed by a pattern. It is packed around a pattern which is the replica of the casting shape. The metal is melted at home and poured into the molds and when it has cooled and solidified, it is taken out as a shiny new metal casting. A hobby metal casting professional can create things to be used for special projects, vintage automotive parts, antique restorations and rebuilding old workshop tools.

For more information on our metal melting and smelting furnace kits, get in touch with the experts at Cast Master Elite today. We have been doing metal casting since 2001 and started out using Petrobond Sand. As a home foundry we know how hard it is to find the tools you need to create great castings. Except the crucible, most or all of the foundry equipment can be easily produced at home for little or no cost. Powerful gas-fired soldering and melting furnaces form the backbone of a productive foundry classroom.

Featuring Foundry Supplies for the Commercial Foundry

Purchasing one of our metal melting furnace kits means you’ll have everything you need to get started the second you receive your new smelting furnace kit, aside from the metal you’ll be melting and the propane to heat it! Made from heavy-duty stainless steel construction, Kaowool ceramic insulation, a refractory cement floor, and heat-resistant fire brick, your propane smelting furnace is made to withstand any project. These versatile tools can be used for jewelry smelting equipment, blade smithing equipment, and all your general blacksmithing needs.

If you’re interested in casting other sorts of metal, you can check out our article “Metal Casting At Home – A Getting Started Guide” here. Most of the foundry equipment is easily available for little or no cost. A good home foundry can be setup for a fraction of the cost when compared to buying a metal part. When creating a part or component, you can easily make other components by pouring some extra sand. All about industrial applications of metal casting technologies in Automobile, Industrial Machinery.

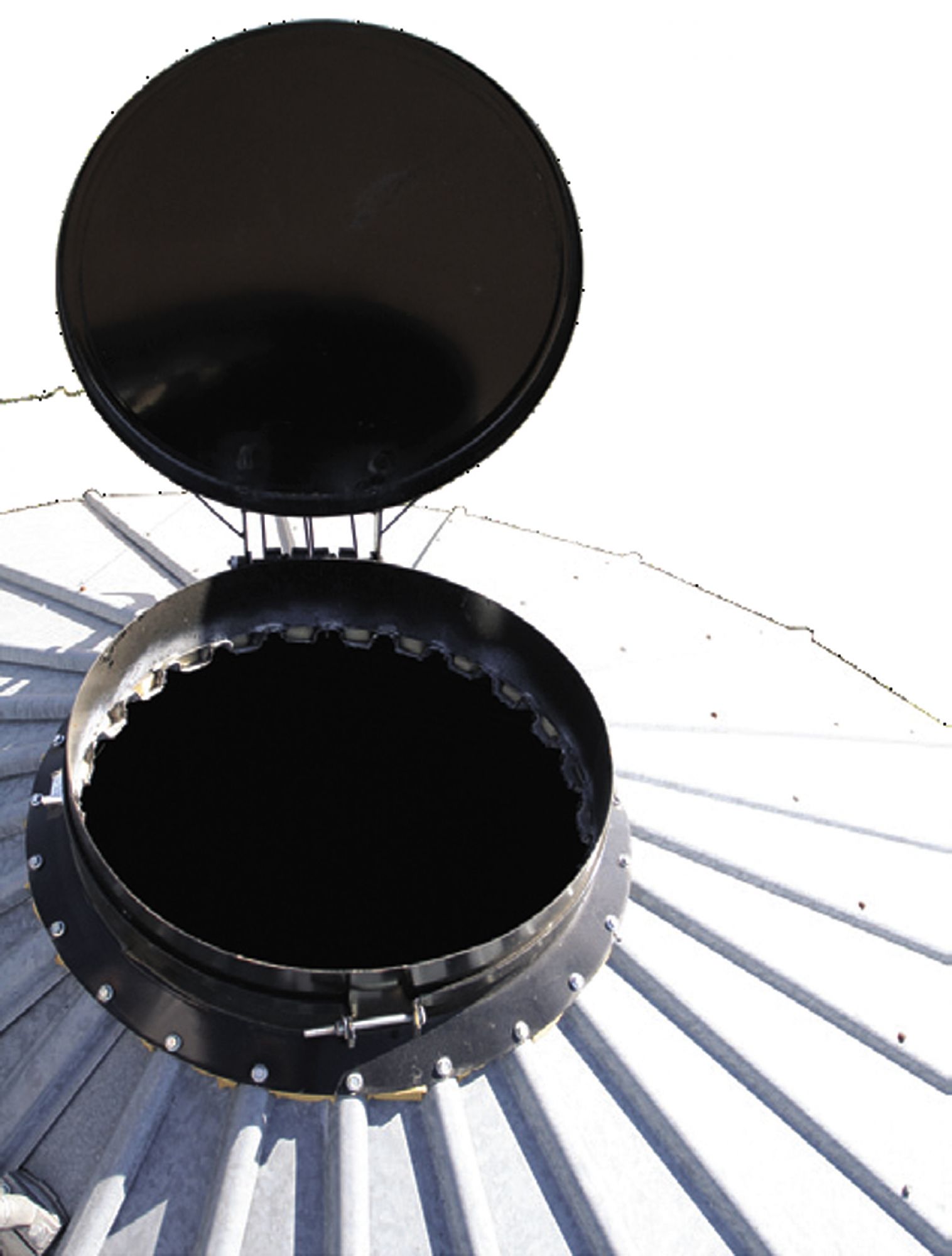

While doing this step, be careful to make two sets of keys for the sides of the flask. It is essential that the cope and drag fit the flush in a consistent manner, so that the mold will separate cleanly at the parting line. To design a simple flask for uses in home foundry, first of all find yourself some clear, straight 1 X 4 and cut off 8 sections from it. Of these 8 sections, 4 should be of 10" in length and other 4 about 12" long. Then clip off eight 2" slices and make the pair of boxes. Use glue and wood screws to keep the boards together. After selecting a suitable furnace vessel, develop it by first slicing off its lid - near the top most seam—then cut a hole in its side, near bottom.

The side of aluminum exposed to the outside forms a layer of crystallized metal on its top but this can be dealt with when the castings are machined. Home foundry can be defined as basic metal casting facilities setup in the home or backyard by hobby metal professionals to make small castings for various needs. A home foundry is different from a commercial foundry in the way it is generally setup using things and equipment that are easily available in the market and can be used to perform simple metal casting works. Metal casting is an amazing, however, quite a simple process that can be used to make a variety of things, with your skill and imagination as the only limiting factors. From the concept of design through to pattern production and finally to mold making , all these processes can be easily performed in a home foundry.

Our apartment is in the centre of Amsterdam on the South part of the canals near the 'Spiegelgracht' where all the art galleries are. KIT Royal Tropical Institute is an independent centre of expertise and education for sustainable development. We assist governments, NGOs and private corporations around the world to build inclusive and sustainable societies, while measuring their impact.

Based at a national heritage site in Amsterdam, KIT Royal Tropical Institute is an independent centre of expertise, education and hospitality dedicated to sustainable development. We use all the products that are sold in our shop so it’s easy to provide a 100% Guarantee. It offers an excellent overview of the many options available, allowing the reader to make the best choices for their individual situation during the design, installation, and operation of a solar electric system. All the basics are thoroughly covered, such as well water, septic and sewage disposal, and off-the-grid energy options .

You need not find a source or pay for metal parts which you require for some mechanical device or vehicle. Moreover, you have put to good use all those small pieces of scrap metal, which were good for little else. Next time when you need the same component, you don't have the make the mold and some extra efforts, which you did the first time.

Comments

Post a Comment